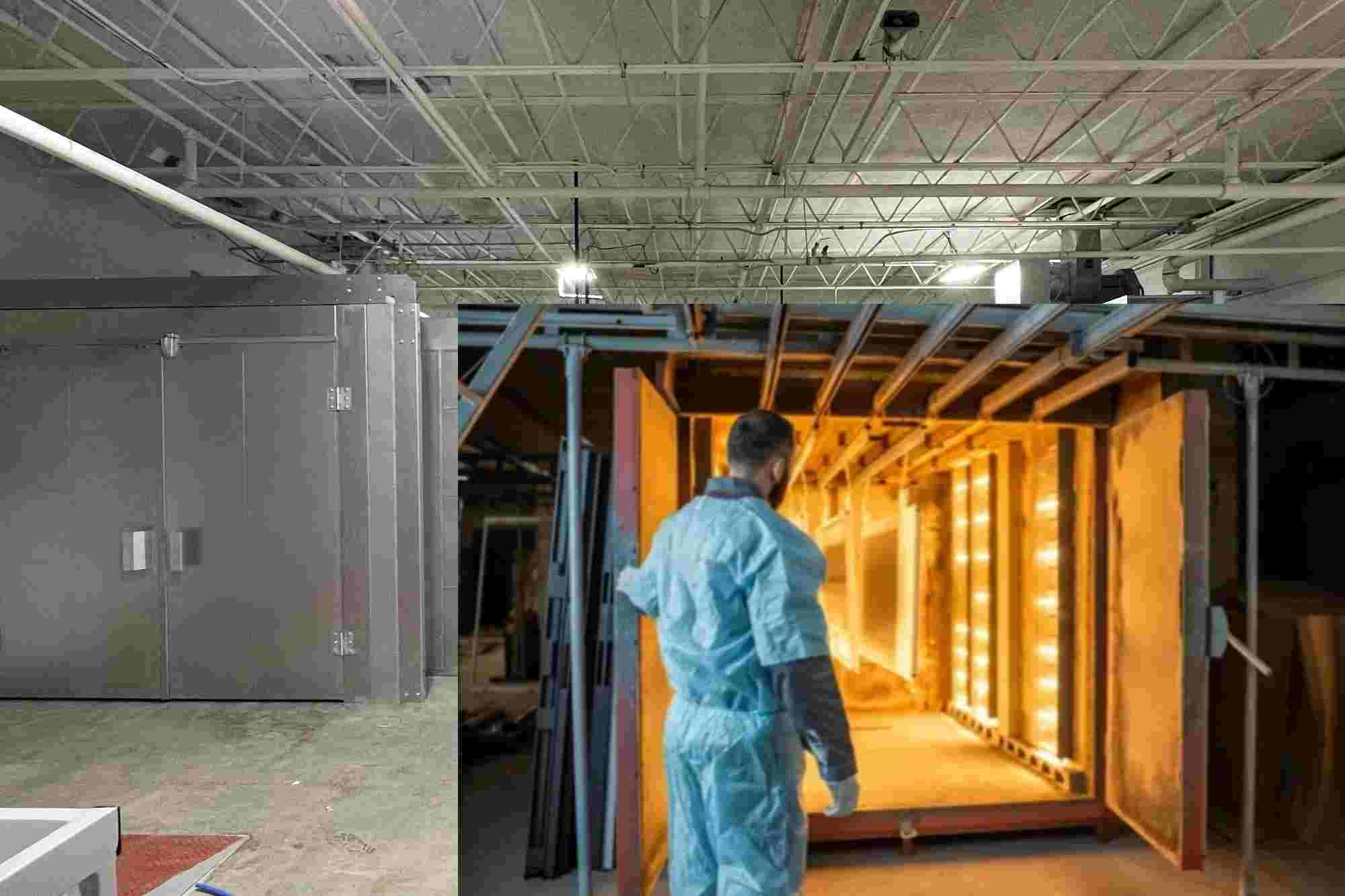

Equipment performance often hinges on details that are easy to overlook during purchasing decisions. In powder coating operations, the oven is not just a heat source but a structural system that influences consistency, efficiency, and long-term reliability. Understanding how construction choices affect results helps buyers evaluate powder coating ovens beyond surface specifications.

Oven Frame Strength Affects Long-term Stability

The oven frame forms the backbone of the entire curing system. A rigid, well-engineered frame keeps panels aligned and doors square even after years of repeated heating and cooling cycles. Weak framing can flex under thermal expansion, leading to misalignment that affects airflow and temperature balance.

Structural instability can show up as sticking doors, uneven seals, or warped openings over time. These issues quietly undermine curing consistency. Industrial powder coating oven designs with reinforced frames maintain their shape under load, protecting both the oven and the quality of finished parts.

Curing Chamber Insulation Controls Heat Efficiency

Insulation quality directly affects how evenly heat is retained inside the curing chamber. High-grade insulation minimizes heat loss, allowing the oven to reach and hold target temperatures without constant burner cycling. This stability supports consistent cure profiles across every rack. Lower-quality insulation allows heat to escape through walls and ceilings, creating temperature swings that affect finish quality. In powder coating systems, inefficient insulation also drives up fuel and energy costs. Buyers reviewing powder coating equipment for sale often underestimate how insulation impacts both performance and operating expense.

Door Seals Stop Temperature Loss During Cycles

Door seals play a larger role than many realize. Every time doors close, seals must contain heat while allowing smooth operation. Poor seals allow hot air to escape, forcing heaters to compensate and creating uneven temperatures near entry points.

Consistent sealing ensures that curing conditions remain stable from start to finish. Over time, durable seals reduce wear on heating components and maintain predictable results. Well-built powder coating ovens use materials that resist compression and heat degradation across thousands of cycles.

Rack Support Design Keeps Parts Evenly Spaced

Rack support systems determine how parts move through the oven and how evenly heat reaches each surface. Weak or poorly spaced supports allow racks to sag or shift, causing inconsistent airflow around parts. This can lead to undercured or overcured areas within the same batch.

A strong rack support design keeps parts positioned correctly throughout the cycle. Powder coating equipment packages that account for load distribution improve repeatability and reduce rework. Structural integrity here directly affects finish quality, especially on large or heavy components.

Oven Ventilation Avoids Hot or Cold Pockets

Ventilation controls how heat circulates inside the curing chamber. Poor airflow design creates hot and cold pockets that cause uneven curing. These inconsistencies may not be visible immediately but often show up as adhesion issues or premature coating failure.

Effective ventilation distributes heat evenly across the chamber. Properly placed exhaust and circulation points help maintain uniform temperatures. In powder coating equipment, thoughtful ventilation design separates reliable curing systems from those that require constant adjustment.

Temperature Sensors Rely on Solid Mounting Points

Temperature sensors only provide accurate readings when mounted securely and correctly. Weak mounting points allow sensors to shift, vibrate, or read localized temperatures instead of overall chamber conditions. This leads to inaccurate control decisions.

Solid construction ensures sensors remain fixed in optimal locations. Reliable data allows control systems to respond correctly and maintain consistent cure profiles. Powder coating oven for sale listings may highlight sensor technology, but mounting quality is just as important as the sensor itself.

Curing Ovens with Quality Wiring Reduce Failures

Electrical wiring inside curing ovens is exposed to high heat and constant cycling. Low-grade wiring degrades faster, leading to shorts, intermittent faults, or complete system shutdowns. These failures often occur without warning and disrupt production schedules.

High-quality wiring rated for elevated temperatures extends system reliability. Proper routing and protection prevent insulation breakdown. Industrial powder coating oven construction that prioritizes electrical durability reduces downtime and long-term maintenance costs.

Structural Build Limits Distortion Under Heat Stress

Repeated exposure to high temperatures causes materials to expand and contract. If structural components are not designed for this stress, distortion occurs over time. Panels may bow, seams may open, and alignment issues develop.

A well-engineered structure accommodates thermal movement without losing integrity. Powder coating systems built with heat stress in mind maintain alignment and sealing even after years of operation. This stability protects both performance and safety.

Sheet Metal Thickness Influences Overall Durability

Sheet metal thickness affects how well the oven withstands daily use, impacts, and thermal cycling. Thin panels dent easily and transfer heat unevenly, while thicker panels provide strength and better thermal mass.

Durable construction resists damage from loading equipment and routine maintenance. Powder coating equipment packages that use heavier-gauge steel often outlast lighter builds in demanding environments. Thickness may not be obvious at first glance, but it plays a major role in long-term value.

Reliant Finishing Systems helps manufacturers evaluate oven construction details that impact curing performance and durability. Their team designs and builds powder coating ovens with attention to structural integrity, airflow, and thermal stability. Thoughtful construction ensures curing systems deliver consistent results and dependable operation over time.

Please explore our site for more exciting content if you like this article.